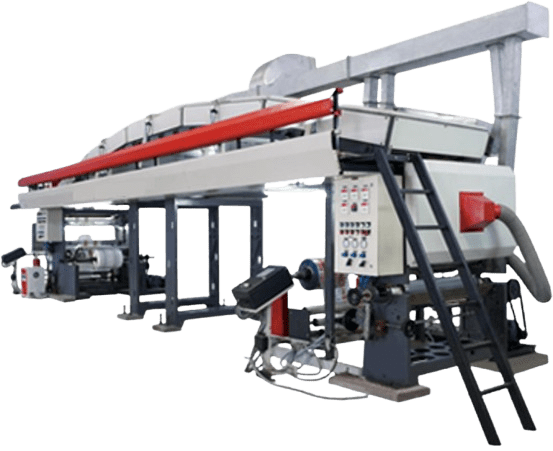

SOLVENT BASE LAMINATION MACHINE

HIGH SPEED LAMINATION MACHINE

SOLVENT BASE MODEL

HIGH SPEED LAMINATION MACHINE

KM TRIVEDI presents the ultimate lamination machine – LAMIMATE which is easy to handle, install and operate. It takes care of large quantity of lamination work in a non messy & organised manner. KM TRIVEDI currently offers two models Standard and High Speed.

24H

TOP END MODEL

HIGH SPEED LAMINATION MACHINE

Technical Specifications:

- Web Width : 800 – 1600mm

- Unwind Rewind Diameter : 600 – 1000mm

- Hot Air Temp : 50 – 150 / 250°C

- Machine Speed : 60 – 200 M/Min.

- Heat Source : Hot Air Generator (Optional)

- Exhaust : 5 HP

- Synchronized Drive : 5 HP/5 / 7.5,10 / 3 HP for Coater , Nip, Rewind & Positive Drive (Optional)

- Material to be Laminated : Polyester/Poly/Paper/BOPP/ Aluminium Foil/HDPE Fabrics etc.

UNWIND STATION: Tension control Brake Unit with load cell feedback (Electrical/Pneumatic). Moveable unwind with web guide.

COATING UNIT: Independent AC Drive. Pre – Heating / Exhaust.

DRYING CHAMBER:

- Load cell feedback for coating & Nip.

- Pneumatic lifting of top door.

- Cat walk for full length drying chamber.

- Programmable Temperature Control.

- Positive tunnel drive.

HOT AIR GENERATOR: Diesel / Coal or Wood Fired Air Heater / Thermic fluid Heater with Blower.

DRY LAMINATING UNIT: Web Chaser

REWIND STATION: A. C. synchronize Drive with Load cell. Centre winding system/ Surface.

OPTIONAL ATTACHMENT: Air Shaft, Pull roll assembly ( In feed drive ) , May bar / Reverse roll, Air knife Three roll. , Wet Lamination arrangement. , Extra blower & Exhaust Individual for each zone. , Chill Roll. , Bow Roller., Ink Circulating with Viscosity Control. , Touch Screen Operated control for all drive.

24H

STANDARD MODEL

SALIENT FEATURES

Heavy duty C.I. Cast iron & Heavy fabricated structure. Gravure type coating system. Cantilever type impression pressure assembly actuated with pneumatic piston for rubber roll Doctor blade and Nip Roller. Fully insulated imported special glass wool sheet fitted in the panel (Top side & Bottom ) For controlling heat loss. One & One Slit type counter air flow arrangement, Divided equally are placed against roller for proper web support. Exhaust are distributed through-out the length of drying chamber & individual exhaust duct for each zone. Digital temperature controller with indicator & AT 100 sensor for each Zone. Inside heating for Nip Steel roller. Heavy duty Shaft types fix Rewinder with motor. KMT SRA Web system for controlling the Web after the drying tunnel & two web for primary & Secondary unwind.