Air Shaft Manufacturers

Leading the Industry with Precision-Engineered Air Shafts

Top Air Shaft Manufacturers and Exporters in India – KM Trivedi

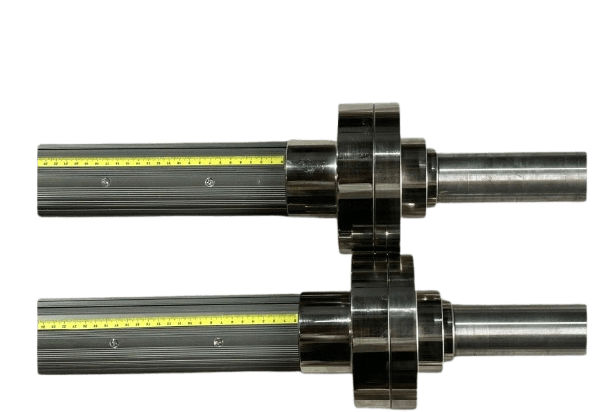

Air shaft is a special shaft for winding and unwinding. The shaft is designed by the key/leaf/lug on the surface, which will be expanded when the high-pressure gas filled enter into the shaft inside. The customer just aired the shaft through the air valve and when user want to lock the coils or web, and just push the core of the air valve to deflate, the keys will revert to its original appearance, then web can be dismantled simply.

Expanding shafts are widely used for winding, rewinding slitting , printing, packaging, plastics, paper, glass, pharmaceuticals, electronic battery, textile machines or industries.

6 inch Core shafts and expanding shafts are used to handle winding rolls in the processing of web-fed materials. They are worked with equipment such as continuous-process printing machines. Mandrels and air shafts are similar to the axles on an auto. They apply as the connection between the motor that drives the reel-winding application and the roll itself.

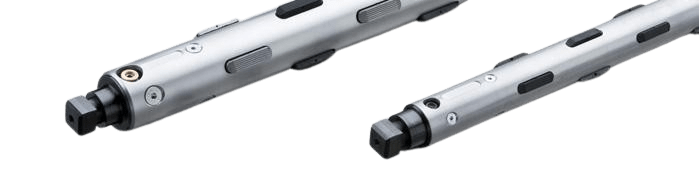

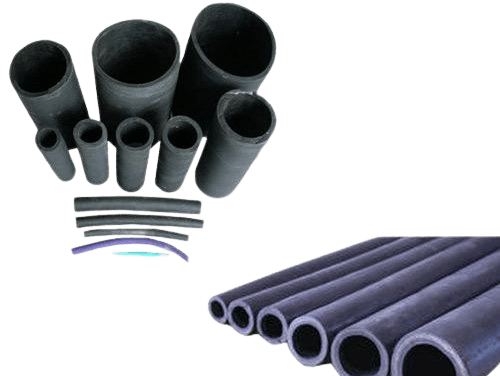

Different models of air shafts and core shafts.

- Standard Air Shafts(Lug type or Leaf Type)

- Internal Bladder Air Shafts(Single Bladder Type)

- External Bladder Air Shafts(Multi Bladder type)

- Differential Air Shafts

- Slitter Knife Shafts

3/ 6 inch Pneumatic shaft features:

(a). Lightweight structure: Reduce the risk of operator injury, light weight (aluminum alloy).

(b). High roundness and less jitter: The circumference is eight equal parts and the force is uniform, which can replace the traditional leaf air shaft.

(c). Simple maintenance and easy assembly and disassembly: Upper and lower two-piece press key design: Bladder replacement can be easily done without disassembling the entire shaft.

(d). Imported transparent flat airbag, long service life and low maintenance rate.

(e). Internationalization of quality and localization of prices.

Technical parameter

Model | Inner Diameter of Paper Tube | Shaft Diameter Before Expanding | Shaft Diameter After Expanding |

1″ Shaft | Φ25.4mm | Φ24.5mm | Φ27.5mm-Φ28mm |

1.5″ Shaft | Φ38mm | Φ37mm | Φ41mm |

2″ Shaft | Φ50mm | Φ49mm | Φ53mm |

3″ Shaft | Φ76.2mm | Φ74mm-Φ74.5mm | Φ82mm |

4″ Shaft | Φ102mm | Φ100mm | Φ108mm |

6″ Shaft | Φ152.4mm | Φ150mm | Φ158mm |

8″ Shaft | Φ203.2mm | Φ200mm | Φ210mm |

10″ Shaft | Φ254mm | Φ250mm | Φ260mm |

12″ Shaft | Φ304.8mm | Φ300mm | Φ312mm |

BOOKING FORM

LUG AIR SHAFT

24H

Rubber Lugs

Grippers are slit through the metal pipe and pneumatic bladder is used for inflating.

The grippers give positive holding of the core.

→ These shafts are strong & rigid

→ Standardized design allow us to manufacture the shaft in any size

→ The same design can be offered for heavy duty to light capability shaft

→ Simple design ensuring long service

→ Staggered lug design makes it best in winding application

→ Each gripper offers a designed chamfer for easy core insertion

→ Dimensional tolerance of journal is very tight for better fitting & rigidity during operation

Material Pipe : Steel or Aluminum, Carbon Fiber

Lugs : Steel, Rubber or Plastic

Available Size Core ID from 3″ to 8”

Length up to 6000 mm (240″)

24H

Metal Lugs

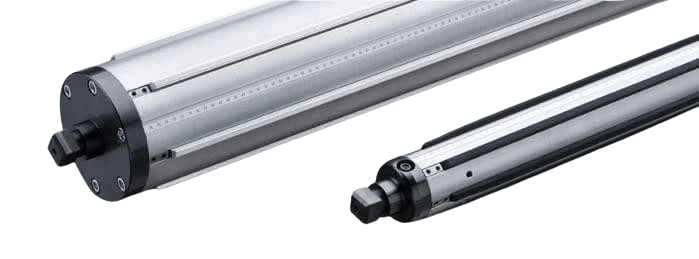

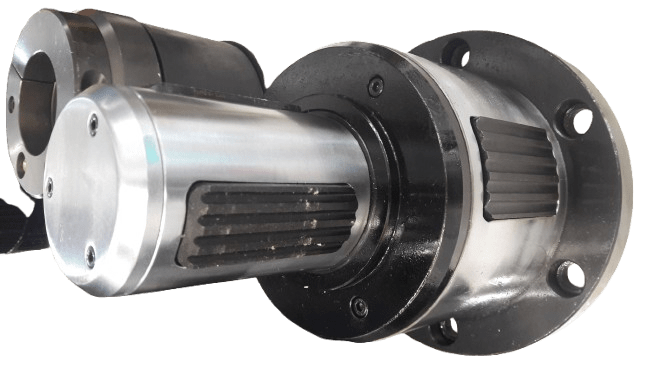

MULTI BLADDER AIR SHAFT

The Multi Bladder Shaft is made of Aluminum Extrusion with steel journals Tight -fitted for High Torque capability. It is assembled with a PU tube for longevity.

→ These shafts are strong & rigid

→ Standardized design allow us to manufacture the shaft in any size

→ The same design can be offered for heavy duty to light capability shaft

→ Simple design ensuring a long service

Externally Lug Type Expanding Shaft with Wedge type design makes it possible for concentric holding and allow high speed winding.

→ Heavy spring is applied for ensuring sliding back of lugs.

→ True mechanical advantage is used in achieving heavy clamping force

→ Absolutely maintenance free as no rubber components or lubrication

24H

MULTI BLADDER AIR SHAFT

MECHANICAL EXPANDING SHAFT

24H

MECHANICAL EXPANDING SHAFT

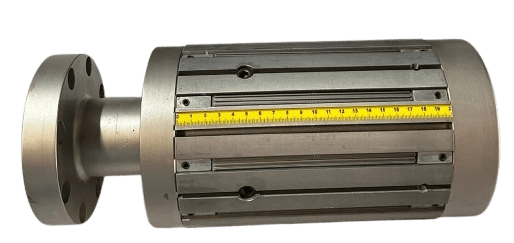

CANTILEVER SLITTING MACHINE SHAFT

24H

CANTILEVER SLITTING MACHINE SHAFT

CANTILEVER SHAFT 6 INCH

24H

CANTILEVER SHAFT 6 INCH

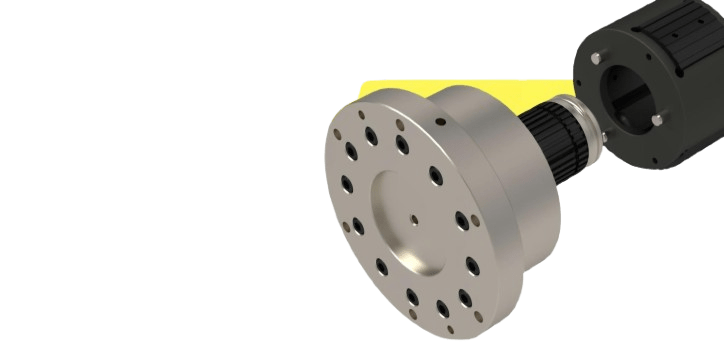

MULTI BLADDER CHUCK

24H

MULTI BLADDER CHUCK

POWER CHUCKS

Variant of the Multi Bladder shaft with through bore inside for holding on a shaft

→ No direct contract with Rubber Bladder

→ Less Maintenance cost

→ Highly Reliable & concentric

→ Great option for retro fitting existing Shaft or rod

Material Body : Aluminum, Steel in special case

Gripper : Rubber, Plastics and aluminum

Available Size; 8″, up to 12″

24H

POWER CHUCKS

BALL LOCK

Most widely used friction elements for Differential winding. Steel, Aluminum or Engineering Plastic body specially manufacture to act as gripper with Ball.

→ Usable for various differential shaft as replacement

→ Designed for high speed and Concentric holding

→ Fully covered ball makes the dust problem almost nil

Material Base : Alloy steel & bronze &

Engineering Plastic

Ball : Stainless steel

Available Size Core : 25mm, 50mm, 70mm

3′ , 4″, 5″, 6′, & 8″

Width: 24mm onwards

It is a simple bellow type chuck mounted on an aluminum body for holding up the reel. It is used with a side clamp or a set screw on the base shaft.

→ Economical & light weight solution for core holding

→ Widely used for low torque unwind operation

→ Absolutely no damage to core

→ Easy mounting on shaft

Material Body : Aluminum Alloy, Bladder : Rubber Polymer

Available Size Core ID 6″ onwards

Bore ID square or round as per customer requirement

24H

BALL LOCK

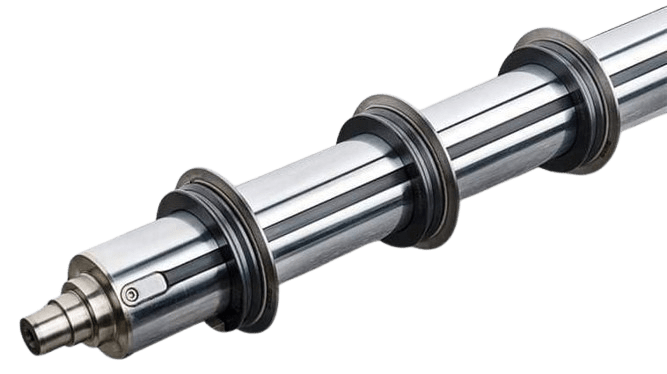

FRICTION SHAFT

A Shaft specially designed for slitters to handle constant tension on multiple slit. The base steel shaft has multiple bladders, mounted with Ball Locks for reel holding.

→ Small width winding possible at very low web tension –

→ A solution for Sensitive Material.

→ Each slit material can slip at different speed and same tension.

→ Ball lock with spring design minimizing side movement while setting and running.

→ Automatic tension controlling through rotary union in dynamic condition

by signals from machine drive.

Available Size50mm, 70mm, 3″, 4″, 5″, 6″ –

any size possible

Minimum ball lock width

24 mm onwards

24H

FRICTION SHAFT

TORQUE CHUCK / THRUST CHUCK

Cam type shaft makes the chuck hold core in positive gripping position.

→ Concentric chuck expansion

→ No side arm force required

→ Gripping is better at high torque application

→ Comparatively lesser damage to the core

- Material Alloy steel

- Available Size3″, 4″, 5″, 6″, up to 12″

24H

TORQUE CHUCK / THRUST CHUCK

BOTTOM KNIFE HOLDING

→ Fundamentally a Multi Bladder Shaft with tight-tolerance

→ External body which holds anvils or knives precisely in place for slitting operations.

24H

BOTTOM KNIFE HOLDING

( MULTIBLADDER AIR SHAFT TUBE )

Material Body : Alloy steel, Hard Chrome Plated & Hardened

Lugs : Aluminum, Steel and Rubber

Available Size The shaft’s outer diameter ranges from 50 mm to 300mm, Length up to 3 meters

24H

( MULTIBLADDER AIR SHAFT TUBE )

Unmatched Export Quality for Global Markets

KM Trivedi is not just a domestic leader but also a globally recognized exporter. Their air shafts meet international standards and have gained demand across Europe, the Middle East, Southeast Asia, and Africa.

With a robust logistics system and adherence to strict quality control, KM Trivedi ensures hassle-free export and reliable packaging.

Custom Air Shaft Solutions for Every Industry

No two industries are the same. KM Trivedi understands this and offers fully customizable air shafts. Whether you need specific diameters, core materials, or shaft lengths — their in-house engineers deliver with precision.