Precision Slitting Line Tooling & Rotary Cutter Solutions

Slitting Line Tooling / Circular Slitter Knives / Rotary Slitter Knives / HR & CR Slitting Cutters

High Speed Steel Slitter Knives / Rotary Slitting Blades & Rubber Spacers

HSS Slitter Cutters / Circular Slitter Cutter / High Speed Steel Slitter Knives

Slitting Machine Blades / Rotary Shear blades / Circular Slitting Blades

Roll Shear Knives / Rotary Shear Knives / Crush Cutter / Round Slitting Cutters

INDUSTRIAL CUTTERS- KM TRIVEDI

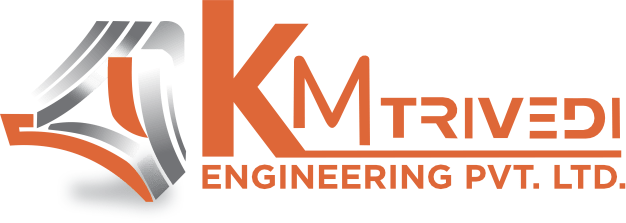

KM Trivedi offers a wide range of slitting line tooling and rotary cutter knives, crafted with high-grade materials and cutting-edge manufacturing technology to ensure precision, durability, and performance for your industrial cutting needs.

Applications:

-

Steel processing lines

-

Paper and film industries

-

Non-ferrous metal industries

-

Plastic and rubber manufacturing

-

Coil-to-coil slitting lines

Our Product Range Includes:

-

Circular Slitter Knives / Rotary Slitter Knives

Perfect for high-speed slitting operations in steel, aluminum, copper, and other materials. -

HR & CR Slitting Cutters

Designed for Hot Rolled (HR) and Cold Rolled (CR) steel applications, ensuring clean and burr-free cuts. -

High-Speed Steel (HSS) Slitter Knives & Cutters

Manufactured using premium HSS M2, M35, or M42 grade for exceptional hardness and wear resistance. -

Rotary Slitting Blades & Rubber Spacers

Maintain accurate slit width and reduce vibration with perfectly balanced tooling accessories. -

Slitting Machine Blades / Circular Slitting Blades

Engineered for precision and longevity, suitable for both narrow and wide coil slitting lines. -

Roll Shear Knives / Rotary Shear Blades

Built to withstand heavy-duty applications with exact edge geometry and tight tolerances. -

Crush Cutters / Round Slitting Cutters

Ideal for non-metallic material slitting like paper, plastics, films, and textiles.

CUTTER

Slitting Machine Blades / Rotary Shear blades / Circular Slitting Blades

Roll Shear Knives / Rotary Shear Knives / Crush Cutter / Round Slitting Cutters

CUTTER

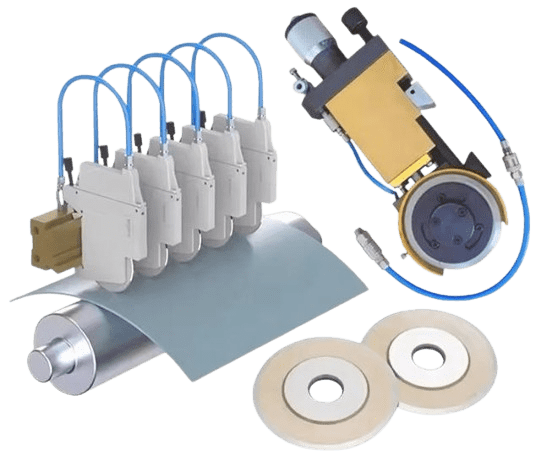

CIRCULAR KNIVES

|

Size (Diameter) |

10 Inch |

|

Application |

Industrial |

|

Brand |

K M TRIVEDI |

|

Material |

HSS,D2 |

|

Hardness |

64 HRC |

|

Nominal Chemical Composition |

0.8% |

|

Material Grade |

T1 |

CIRCULAR KNIVES

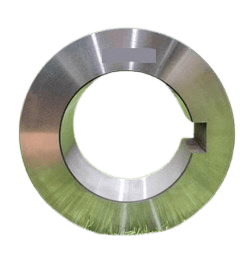

BOTTOM SLITTING CUTTER FOR SLITTING MACHINE

|

Size/ Diameter |

110 mm |

|

Thickness |

0.5 mm |

|

Material |

HSS |

|

Shape |

Round |

|

Usage/Application |

Slitting Cutter |

|

Brand |

K M TRIVEDI |

|

Country of Origin |

Made in India |

Km trivedi boasts of specialization in manufacturing custom circular slitter knives and rotary slitting blades per sample and drawing. If you need your circular slitter knives and rotary slitting blades manufactured to your exact requirements, please contact us now to see how we can make high quality circular knives and blades exceeding your requirements at a competitive price and always delivered right on time.

BOTTOM SLITTING CUTTER

Paper Slititng

|

Usage/Application |

Paper Slititng |

|

Shape |

Circular |

|

Packing Type |

Corrugated Box |

|

Brand |

K M TRIVEDI |

|

Material |

HSS |

|

Nominal Chemical Composition |

0.85% |

|

Material Grade |

M2 |

|

Hardness |

64 HRC |

K M TRIVEDI is constantly working on the development of Slitter Knives and its material.

This ensures an optimal balance between the determination of the knife material and the tuned heat treatment processes.

So we are able to provide you the best solution for your cutting application.

We produce rotary slitter knives in different tolerance classes to meet the requirements of our customers.

Paper Slititng

Metal Shearing

|

Thickness |

5 mm |

|

Material |

HSS |

|

Shape |

Circular |

|

Brand |

K M TRIVEDI |

|

Usage |

Metal Shearing |

|

Material Grade |

M1 |

|

Nominal Chemical Composition |

0.8% |

|

Hardness |

64 HRC |

K M TRIVEDI manufactures Roll Shear knives for Slitting & Trimming lines. Material used is forged alloy tool steels, high speed steels. Heat treatment is monitored and is processed by controlled equipment. Material selection and hardness values according to the knife applications. Precision and “Ultra Precision” Tolerances are available as per requirement. Surface finishes available are ground, lapped and polished.

Metal shearing

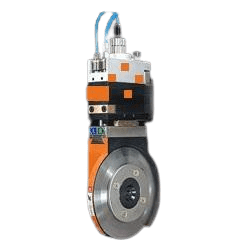

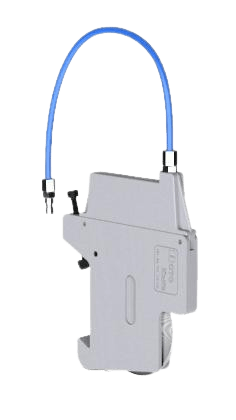

PNEUMATIC CUTTER FOR SLITTING MACHINE

Use of the knife holder

This version of the PNEUMATIC KMT is suitable for cutting film, foil, and plastic as well as paper, cardboard, carton, and print. However, he is also suitable for solid solid plastics such as polycarbonate. This version also features the 360° safety hand guard, which takes safety in your production to a new level.

Let our experts advise you which knife holder design provides the optimum cutting results in your application.

Your Advantages

- Elimination of slippage thanks to motor-driven knife

- High precision cutting edges

- Precise regulation of the ratios of top and bottom knife and fabric web speed

- Increased knife life

- Shortened set-up times for format changes

- Increased safety due to fewer knife changes

- Automatic depth adjustment

24H

PNEUMATIC CUTTER (SEMY MODEL )

KNIFE HOLDER FOR SLITITNG MACHINE

What is Razor Slitting?

Razor slitting is an industrial cutting method where a sharp, stationary industrial razor blade is positioned across the path of the moving web in a slitter machine. As the material passes the slitter blade, it is cut by direct contact. The resulting cut depends on the characteristics of the web material. These include thickness, density, stiffness, ductility, coating, and other factors. When razor slitting, the material is unwound from the roll, passed through the razor blades, cut in air or in a grooved roll, and finally wound onto cores called spools or bobbins. This technique is commonly used for thin plastic films, where clean, straight cuts are required. Razor slitting is often chosen for its simplicity, low cost, and ability to produce narrow cuts with minimal waste. However, razor cutting has some limitations. It may not be suitable for thicker or tougher materials, and the blades may require frequent replacement due to wear and tear. The optimal range is between 0. 5 and 7 mils (approximately 12 to 175 microns), depending on film type and slitting razor blade quality. While razor slitting can technically cut paper or filled films, blade wear occurs rapidly, making such use cases less practical or economical. Additionally, the process might produce dust or debris, which requires careful removal to prevent contamination or other issues. Despite its speed and wear limitations, razor slitting remains one of the most practical and economical slitting methods. It’s ideal for converters handling flexible packaging, label films, and light laminates.

24H

KNIFE HOLDER FOR SLITITNG MACHINE