NARROW WEB MINI SLITTER REWINDER

Precision and Efficiency by KM Trivedi

Narrow Web Mini Slitter Rewinder – Precision and Efficiency by KM Trivedi

The Narrow Web Mini Slitter Rewinder by KM Trivedi is a game-changer in converting technology. Built for compact spaces yet delivering industrial-grade performance, this machine is ideal for label stock, film, and paper processing. Its robust design, precision engineering, and easy operation make it a must-have for modern production lines.

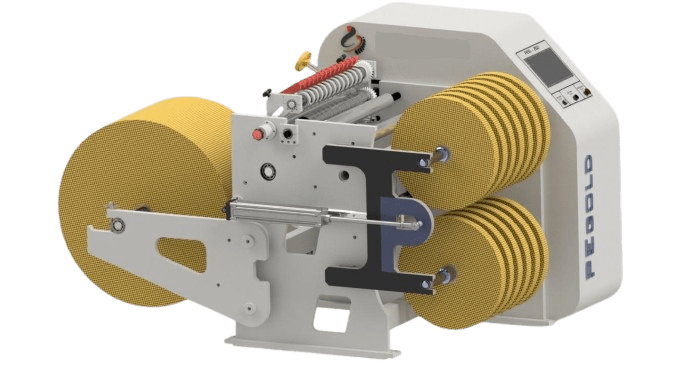

the ideal models for secondary slitting and doctoring purposes. These integral machines are specifically engineered to handle materials with precision and accuracy. With cantilevered unwind and rewind shafts, they offer easy loading and unloading access from one side, enhancing operational efficiency.

KMT DOC 525 is widely utilized in the label and pharmaceutical industries, serving as a doctoring slitter for secondary processes. Its compact design allows it to handle rewind diameters up to 600mm and achieve a minimum slit width of 20mm, making it perfect for doctoring applications.

Additionally, KMT DOC 525 is a popular model for handling glass epoxy used for printed circuit boards, further expanding its versatility and applications

STANDARD FEATURES

- INTEGRAL MACHINE DESIGN WITH CANTILEVERED LOADING & UNLOADING.

- SHEAR, SCORE, RAZOR SLITTING ROTARY CUTTER

- TRIM REMOVAL SYSTEM.

- AIR EXPANSION SHAFTS.

- STATIC ELIMINATOR.

- CONTACT ROLLER.

- AUTO TENSION CONTROL.

- MANUAL UNLOADING SYSTEM.

- PLC CONTROL SYSTEM INCORPORATE WITH HMI TOUCH SCREEN.

DOCTORING MACHINE CUM INSPECTION CUM SALVAGE REWINDER MACHINE

- Key Features of KM Trivedi Narrow Web Mini Slitter Rewinder

Compact Size for limited floor space

High Precision Slitting with minimal edge variation

Variable Speed Control for different materials

Advanced Tension Management for perfect rewinding

User-Friendly Interface with quick setup functions

Low Maintenance Components for long-term use

SALVAGE REWINDER MACHINE

FRONT LOOK ( HIGH END MODEL )

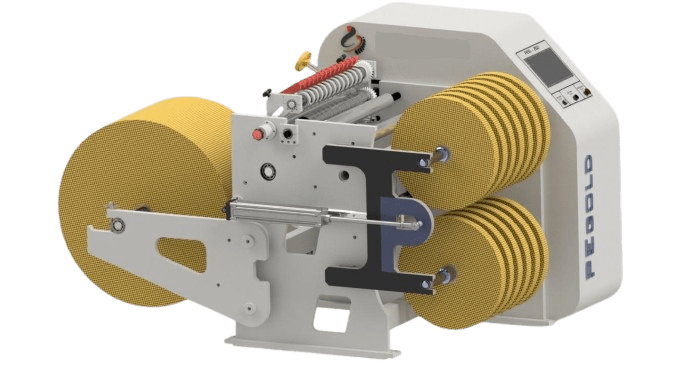

In any paper, film & foil conversion industry, “SLITTING” is invariably the last operation to be performed. At the time of slitting, irrespective of the brand and type of slitting machine employed, ten to twelve percent of the output (i.e. One out of 10 or 8 slit to size bobbins) is not of saleable quality.

This is a Harsh practical fact and the reason thereof are quite well known.

The model is specially designed for correcting badly wound roller for removing the misregistered and rejected material before it goes to final delivery, in order to rectify salvage such rejection, the Doctoring machine has been specially developed through the R & D efforts at K M TRIVEDI .

( HIGH END MODEL )

Narrow Web Slitting Cum Doctoring (Inspection Machine)

FEATURES

- Mechanical Web Gripper & Cross Cutting Slot on Inspection Table.

- Removable Slitting Station

- Adjustable Slitting assembly at the running speed.

- Individual Drive for both rewind station Synchronize with Nip and slitting Drive.

- Speed Indicators Mt. / Min, Length Counter / Batch Counter.

- Inspection Mounting Facility for Strobe Light & Video Vision. Individual Slip ring for each roll.

- Shaftless unwind

- Inject coding table

- Reversable system ( optional )

- Trim winder ( optional )

- Film wastage removal frame etc..

Narrow Web Slitting

TECHNICAL SPECIFICATION

- Web Width: Up to 300 mm / 500 / 700 mm

- Full width machine 1000 mm ( special made )

- Unwind Dia: Up to 800mm

- Rewind Dia: Up to 300 mm Two Stage

- Machine Speed: 200 MPM

- Cutting: Circular & Razor Knife Inspection: system ( optional )