Doctoring Rewinding Machine

Precision and Efficiency by KM Trivedi

High-Performance Doctoring Rewinding Machine by KM Trivedi

A Doctoring Rewinding Machine is a vital solution for correcting, inspecting, and improving the quality of printed and non-printed web materials. KM Trivedi offers precision-engineered machines that enhance productivity, reduce waste, and ensure high-quality output. These machines are designed to meet the requirements of various industries, from flexible packaging to label manufacturing.

- Key Features of KM Trivedi Doctoring Rewinding Machine

-

High-speed operation with consistent tension control.

-

User-friendly interface for smooth operation.

-

Advanced web guiding system for perfect alignment.

-

Robust construction for long-term durability.

-

Adjustable speed controls for different material types.

-

Superior slitting and rewinding accuracy.

Advantages of Using KM Trivedi Doctoring Rewinding Machines

- Improved Quality Control

- Reduced Material Waste

- Higher Productivity:

- Versatile Performance

- Operator Comfort

DOCTORING REWINDING MACHINE ( FOR INJECT CODING AT HIGH SPEED ) CORRECT WOUND REEL INSPECTION ETC. HIGH END MODEL

KM Trivedi offers customizable configurations to meet your needs:

-

Web width: Available from 300mm to 1600mm.

-

Speed: Up to 300 meters per minute.

-

Material compatibility: PET, BOPP, PVC, paper, foil, and laminates.

-

Optional add-ons: Video inspection system, static eliminator, and splice table.

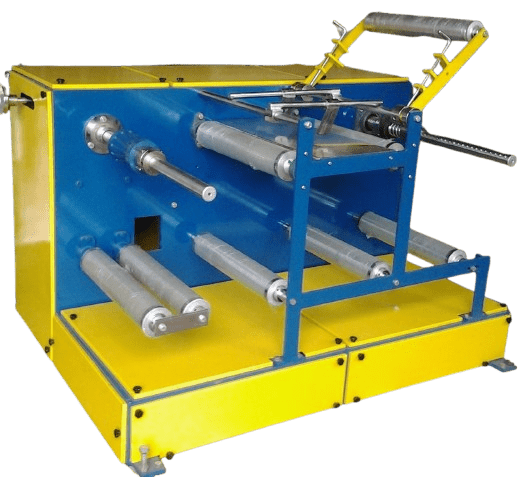

DOCTORING REWINDING MACHINE

TOP END MODEL WITH SLITTING ARRANGEMENT

In any paper, film & foil conversion industry, “SLITTING” is invariably the last operation to be performed. At the time of slitting, irrespective of the brand and type of slitting machine employed, ten to twelve percent of the output (i.e. One out of 10 or 8 slit to size bobbins) is not of saleable quality.

This is a Harsh practical fact and the reason thereof are quite well known.

The model is specially designed for correcting badly wound roller for removing the misregistered and rejected material before it goes to final delivery, in order to rectify salvage such rejection, the Doctoring machine has been specially developed through the R & D efforts at K M TRIVEDI .

TOP END MODEL

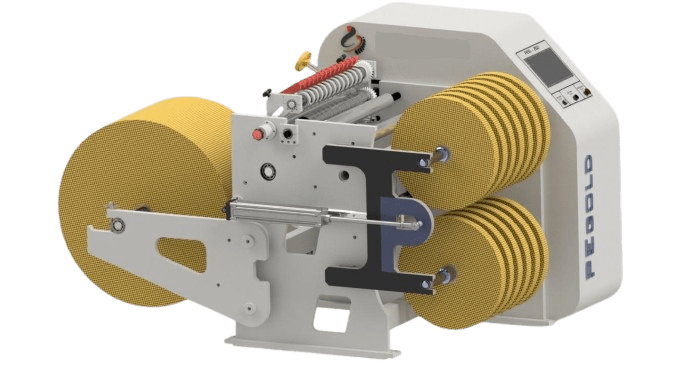

SEMY HIGH END MODEL ( ONLY REWINDING MACHINE )

( ONLY REWINDING MACHINE ) USED TO CORRECT BAD WOUND REEL / SIDE TRIMMING / INSPECTION / REVERSE

SEMY HIGH END MODEL

SEMY HIGH END MODEL ( ONLY REWINDING MACHINE )

In any paper, film & foil conversion industry, “SLITTING” is invariably the last operation to be performed. At the time of slitting, irrespective of the brand and type of slitting machine employed, ten to twelve percent of the output (i.e. One out of 10 or 8 slit to size bobbins) is not of saleable quality.

This is a Harsh practical fact and the reason thereof are quite well known.

The model is specially designed for correcting badly wound roller for removing the misregistered and rejected material before it goes to final delivery, in order to rectify salvage such rejection, the Doctoring machine has been specially developed through the R & D efforts at K M TRIVEDI .

WITH SLITTING ARRAGEMENT

SEMY MODEL

TECHNICAL SPECIFICATION

- Web Width: Up to 300 mm / 500 / 700 mm

- Unwind Dia: Up to 800mm

- Rewind Dia: Up to 300 mm Two Stage

- Rewind Dia: Up to 600 mm Single stage

- Machine Speed: 200 MPM / 250 with synchronised Drive

- Cutting: Circular & Razor Knife Inspection: system ( optional )

SEMY MODEL