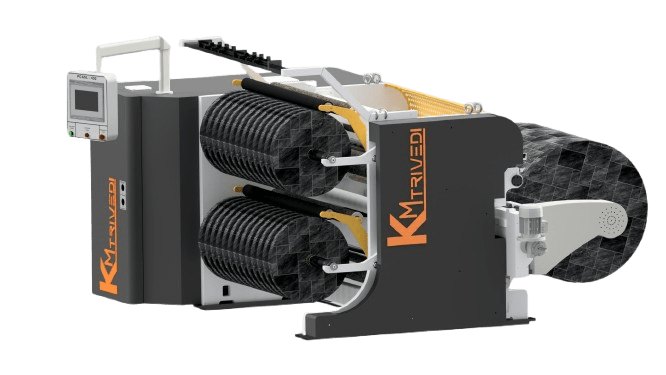

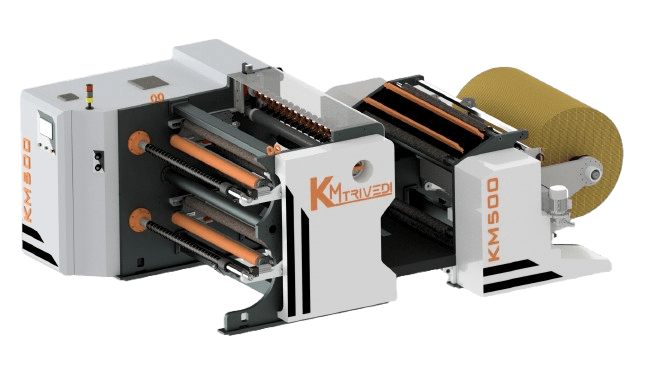

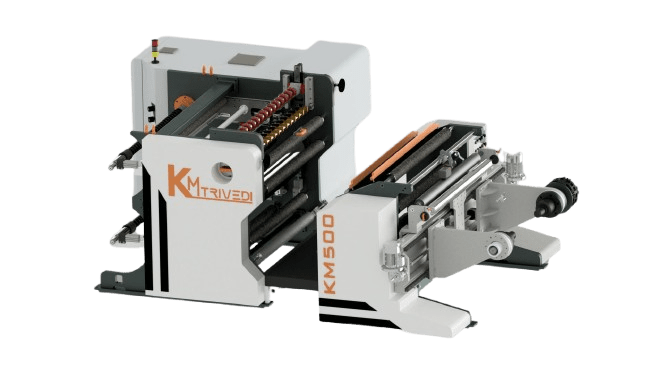

CANTILEVER SLITTING MACHINE

KMT 500 / 575 TURBO – Precision Slitting Redefined

High-Speed Cantilever Slitting Machine for BOPP, PET, Laminates & More

CANTILEVER SLITTING MACHINE KMT 500 / 575 TURBO – Precision Slitting Redefined

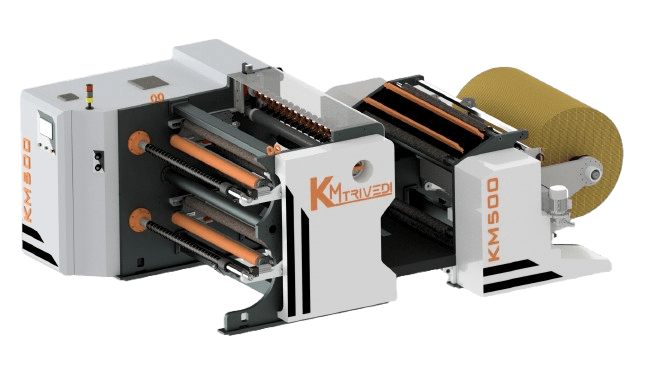

The KMT 500 / 575 TURBO Cantilever Slitting Machine by KM Trivedi is engineered for superior slitting performance across multiple substrates. Whether you’re working with BOPP, PET, LDPE, aluminum foil, or laminated rolls — this machine delivers unmatched speed, accuracy, and reliability.

This cantilever-type design ensures easy loading and unloading, making it ideal for high-efficiency operations and compact workspaces.

Key Features of KMT 500 / 575 TURBO

KM Trivedi integrates modern automation and sturdy mechanics to craft a slitting machine that performs consistently across long runs.

Top Features:

-

Slitting width: 500mm / 575mm

-

High-speed performance up to 300 m/min

-

User-friendly cantilever design for quick roll changes

-

Razor & rotary blade slitting systems

-

Tension control with load cell feedback

-

AC drive-controlled unwind/rewind

-

Pneumatic brake for web tension accuracy

-

PLC-based operation with touchscreen interface

Main technical parameter

|

Jumbo roll width |

1000mm |

1300mm / 1600 MM |

|

Diameter of roll |

1000mm |

1000 mm |

|

Diameter of rewinding |

600mm |

600/800 mm |

|

Inner dia of paper core |

3”(6”) |

3”(6”) |

|

Slitting speed |

10-350m/min/450 |

10-500 m/min/600 |

|

Tolerance of EPC |

+-0.1mm |

+-0.1mm |

|

Min.width of produce |

50mm (20mm) |

50mm (20mm) |

|

Total power |

12KW |

12KW |

|

overall dimension (L X W X H) |

2.3mx3.5mx1.9m |

2.3mx3.8mx1.9m |

|

|

|

|

KM TRIVEDI

Cantilever Differential Slitter Rewinder

24H

MODEL 575 WITH ATTACHED UNWINDER TYPE

Grippers are slit through the metal pipe and pneumatic bladder is used for inflating.

The grippers give positive holding of the core.

→ These shafts are strong & rigid

→ Standardized design allow us to manufacture the shaft in any size

→ The same design can be offered for heavy duty to light capability shaft

→ Simple design ensuring long service

→ Staggered lug design makes it best in winding application

→ Each gripper offers a designed chamfer for easy core insertion

→ Dimensional tolerance of journal is very tight for better fitting & rigidity during operation

Material Pipe : Steel or Aluminum, Carbon Fiber

Lugs : Steel, Rubber or Plastic

Available Size Core ID from 3″ to 8”

Length up to 6000 mm (240″)

24H

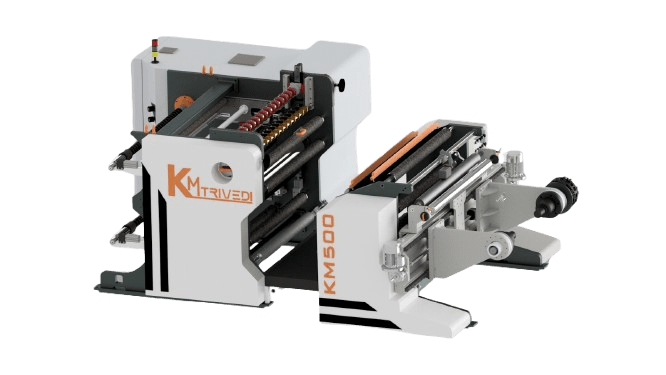

FRONT LOOK

24H

SIDE LOOK

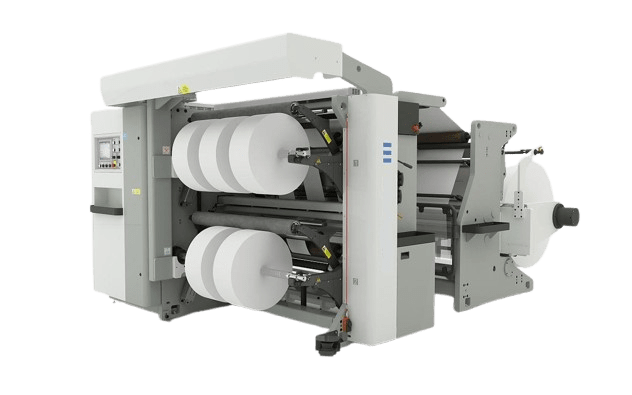

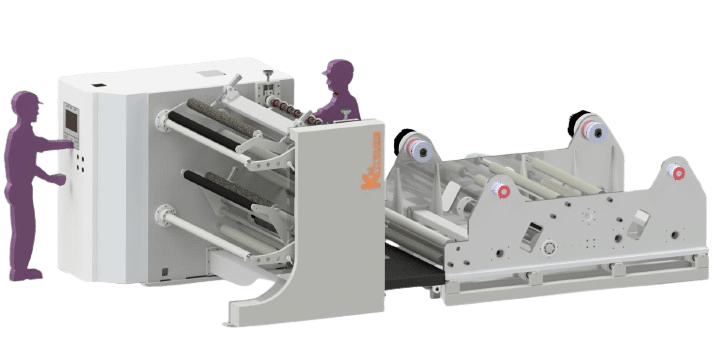

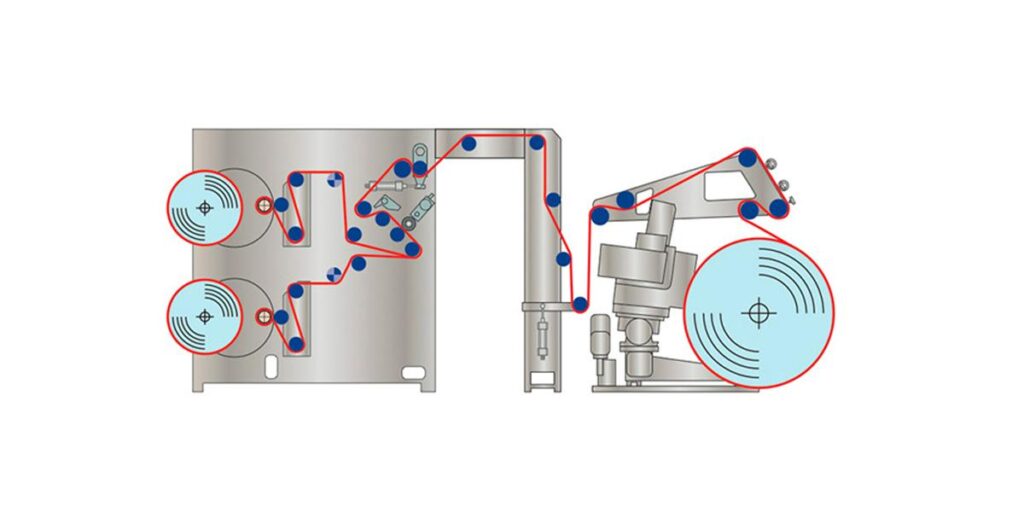

CANTILVER SLITTING WITH DUAL UNWINDER ( FOR SANDWITCH MATERIAL )

24H

CANTILVER SLITTING WITH DUAL UNWINDER

KMT 500/575 TURBO 1000/1300/1600/2000

Uses:

The machine applies to cellophane, POLYESTER FILM / FOIL / BOPP / LD /PRINTED FILMS PET, OPP, CPP,PE, PS, PVC and computer security labels, electronic computers, optical materials, film roll, foil roll, all kinds of paper rolls, film and printing of various materials to slitting.

Features:

1, Unwinding unit: it adopt non-axial Air pressure and get way with Air Chuck, who is caught taking raw materials fast, easy loading, single-person operation.

EPC (Edge position control) use imported LPC corrective device, it can achieve guide function

by material edge as well as printed mark.

Unwinding tension through an independent vector variable frequency electrical parameters of the original pre-computing to achieve a constant tension.

2, Slitting Unit: This machine is equipped with 10 sets of razor knife

(10 sets of circle knife/ Pneumatic cutter as optional)

3, Winding Unit: Rewinding shaft is import friction shaft that’s pressure in center by pneumatic; With automatic tension compensation system, so that rewinding tension is steady, don’t adjust tension in accordance with the speed and diameter increases.

4, Winding sticks pressure unit: The machine is equipped with two sets of pneumatic pressure automatic lifting sticks, tension automatic control by computer.

5, Waste edge processing section: This model is equipped with a vacuum-type waste edge exclusion system, use the strong force adsorb the waste edge out away.

6, Electrostatic elimination Unit: The machine equipped a group of static brush apart on up and down rewinding shaft , which can effectively eliminate the static between slitting and rewinding. (Optional)

7, Finished Produce unloading Unit:

It is a discharge rack can provide a larger diameter of the finished product is simple and efficient to operate and save time for the next feed.

8, PLC control system: Adopt imported PLC to achieve accurate and stable control, true color touch screen display to enable simple and beautiful images. Interactive parameter setting the environment, eliminating the complicated configuration can start the job: The user pre-start only need to input the material thickness, width, density, diameter and speed parameters, the next will be done automatically by a computer calculation to complete.

CANTILIVER SLITTING MACHINE FOR PAPER

24H

SLITTING MACHINE FOR PAPER