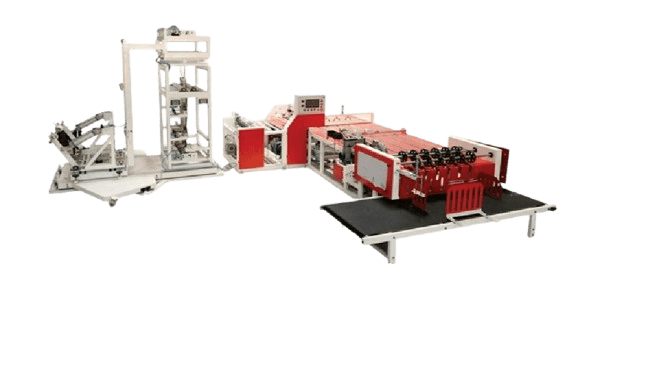

HIGH SPEED BCS MACHINE

Automatic OPP Woven Composite Bag Cutting and Sewing Machine

1.1 Operating Conditions

– Ambient Temperature: 0°C–40°C

– Location: Indoor use only

Key Technical Parameters

|

No. |

Item |

Unit |

Parameter |

Remarks |

|

1 |

Operating Speed |

Bag/min |

40-80 |

Based on 400mm bag length; dependent on speed of sewing machine speed |

|

2 |

Bag Width |

Mm |

200-550/650 |

|

|

3 |

Bag Length |

Mm |

300-1080/1260 |

|

|

4 |

Cutting Precision |

Mm |

±1 |

Color mark tracking |

|

5 |

Material Spec. |

Mm |

φ1200×600 |

max |

|

6 |

Power consumption |

KW |

5/6 |

Running power: 3.5 kW |

|

7 |

Weight |

T |

2.2 |

|

|

8 |

Dimensions |

M |

4.3×5.5×1.4 4.3×5.6×1.4 |

L x W x H |

Automatic OPP

- Peripheral Requirements

- Power Supply: AC380V±10%/3P/50Hz, neutral wire,

- Installed Capacity: 6 kW

- Air Supply: Pressure ≥0.6 MPa

Equipment Overview

- Summary

This machine is designed for producing OPP color-printed woven composite bags.

- Features:

- Fully Automated PLC Control: Touchscreen operation, servo-driven

- Hot Cutting: Anti-stick bag opening mechanism. Imported heat-resistant blades ensure smoke-free, eco-friendly operation (patented).

- Cold Cutting: Low operational cost with easy blade

- Automated Functions: Auto-feeding, edge correction, color mark alignment, handle hole punching, counting, batch delivery, thread break alarm, and fault detection.

- Compatibility: Suitable for fertilizer bags, rice bags, flour bags, putty powder bags, single/double-sided OPP composite bags, and laminated bags.

- Optional: Dual-purpose sewing for open/closed

Component Specifications

- Electrical Components

|

No. |

Components |

Model |

Brand/Origin |

|

1 |

Inverter |

TC300 (5 units) |

BEST |

|

2 |

HMI |

SA2070-30ST |

Taiwan Pantron |

|

3 |

PLC(CPU) |

H2U-3232MT |

Inovance |

|

4 |

Servo System |

3KW |

Mige |

|

5 |

Color Mark Sensor |

LX Series |

Panasonic (Japan) |

|

6 |

Photoelectric Switch |

QL-05N |

Taiwan Yangming |

|

7 |

Contactor |

CJX2-4011 |

Renmin |

|

8 |

Relay |

MY4N-GS |

Omron |

|

9 |

Proximity Sensor |

LJ12A3 |

OMDFON |

|

10 |

Thread Cutting Cylinder |

MAL-25X25 |

Yenor |

Control Instruments

|

Name |

Model |

Manufacturer |

|

Temperature Controller |

Inverter |

Yatai |

- Compressed Air Requirements

- Air pressure: 6 MPa, 0.5 m³/min (user-provided).

- Hydraulic System

- Hydraulic oil: N46 high-grade anti-wear oil (user-provided).

- Operating temperature: 10°C–80°C.

- Cleanliness: NAS Class

- Surface Finish: Off-white textured

2. Scope of Supply:

|

No. |

Item |

Unit |

Qty |

Remarks |

|

1 |

Unwinding Unit |

Set |

1 |

With edge correction |

|

2 |

Cutting Unit |

Set |

1 |

Photoelectric color control |

|

3 |

Collection Table |

Set |

1 |

|

|

4 |

Control Cabinet |

Set |

1 |

|

Inspection Criteria:

- Bag Width: 200–550/650 ++++

- Bag Length: 300–1080/1260 mm (±1 mm).

- Production Capacity: 45–60 bags/min (based on sewing machine speed).

- Equipment Configuration List:

|

No. |

Section |

Component |

Model |

Qty |

Manufacturer |

Remarks |

|

1 |

Un winding |

Unwinding Frame |

500/600 |

1 |

|

Auto edge correction and feeding system reduces labor intensity. |

|

Edge Correction Motor |

110TDY11 5 |

1 |

|

|

||

|

Inflatable Shaft |

500/600 |

1 |

|

|

||

|

Magnetic Powder Brake |

SK2-3 |

2 |

|

|

||

|

Conveyor Motor |

YE2-90L-6 |

1 |

|

|

||

|

Opti onal |

Punching /Handle |

Cylinder |

SDA63X15 -B |

2 |

|

Integratedpunching/handle system reduces labor. |

|

2 |

Cutting Section |

Servo Motor |

3KW |

1 |

|

Servo-driven cutting ensures stability for diverse materials. |

|

Cutting Motor |

0.75KW |

1 |

|

|||

|

Hot Cutting Blade |

620/720m m |

1 |

In-house |

|||

|

Cold Cutting Blade |

620/720m m |

1 |

In-house |

|||

|

3 |

Folding & sewing |

Sewing Machine |

GK20-DN- 2S |

1 |

Shangpeng |

Equipped with folding guide |

|

Conveyor Motor |

|

1 |

Volsen |

|||

|

Folding Guide |

|

1 |

In-house |

|||

|

Thread Cutting Mechanism |

|

1 |

In-house |

|||

|

Speed Adjustment Motor |

YE27124 |

|

|

|||

|

4 |

Collection Table |

Lifting Cylinder |

SC50*65 |

1 |

Yenor |

Adjustable output for continuous or preset batch collection. |

|

Conveyor Motor |

90YSI120 W-4 |

1 |

|