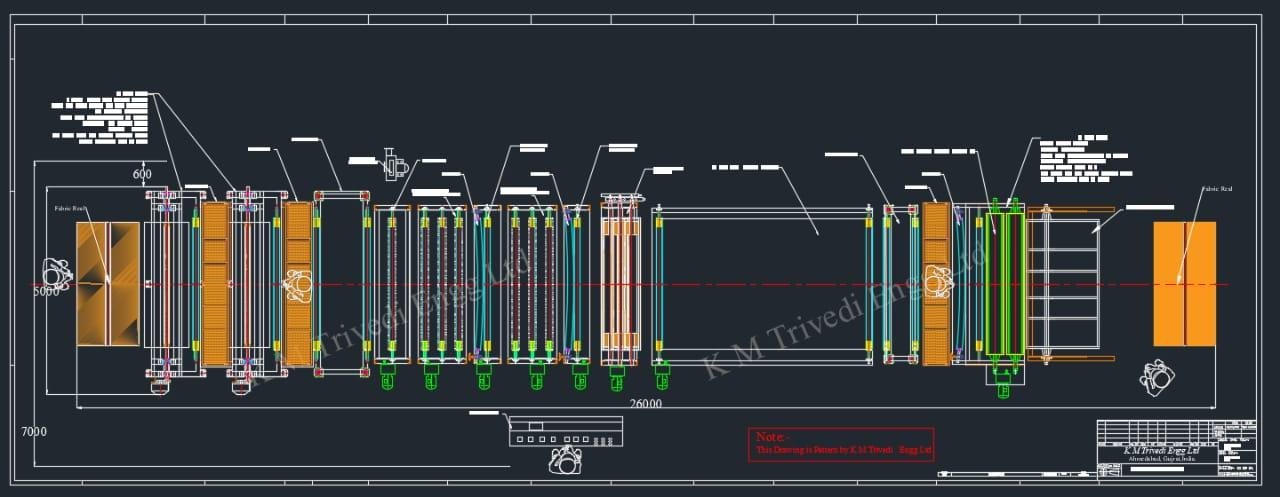

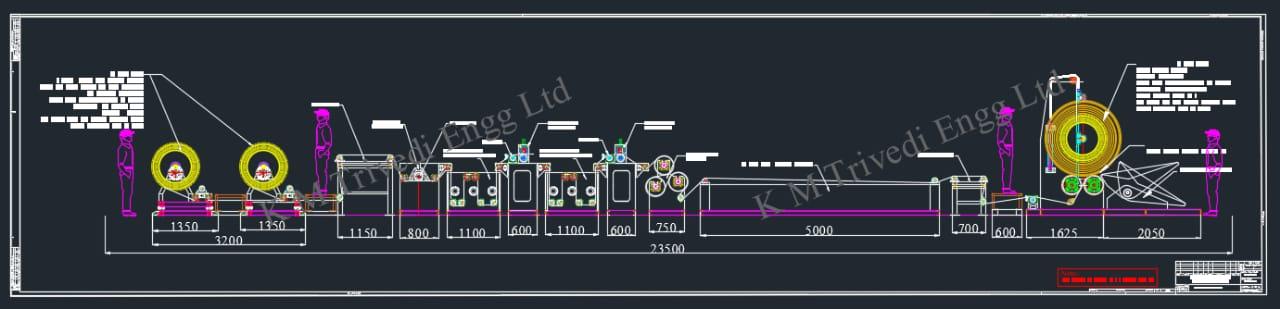

LINER REROLLING MACHINE

FOR TIRE AND RUBBER INDUSTRIES

LINER REROLLING MACHINE

TECHNICAL DATA FOR LINEAR RE – ROLLING MACHINE WITH

FOLLOWING ACCESSORIES

Detail for Liner Re-rolling Machine [Liner Rewinding]

Working width : Mader As Per Requirement

1.) Surface Rewinder [ Wind – up ]

– Heavy duty MS Roll 310 mm Dia. With 60 mm shaft with SNT pillow Block bearing pedestal.

– 6 x 4 MS channel structure for Rewinder.

– 15HP AC motor [ ABB make ] with reduction gear box

– Pneumatic arrangement for core holder shaft

– All gear main drive from standard company.

– Pneumatic pressure arrangement for winding roll and nip unit [ Up / Down Movement ]

Web guiding at rewind

– Pneumatic sensor for position controller moveable re-winder with hydraulic

cylinder and power pack controller.

– Spreader roller 150 mm Dia. With synthetic rubber covering sleeve and angle

adjustment gear box.

2.) Centring system :

– 2 Nos. fabric guider for centring the fabric.

– 1 No. adjusting frame for adjuster LH / RH fabric guider individually as per the width.

– High entry frame structure for fabric guider.

3.) Unwinding Unit [ Let – off ]

– 6 x 4 MS channel structure for Un-winder.

– 50 mm square 2 Nos. Safety chuck holder at both end for holding the shaft.

– 1 No. mechanical shaft with core holder [76 mm. Dia.] with check nut.

– 2 nos Pneumatic brake at both and of safty chuck

Safety chucks for Let-off

4) Nip unit(pul roll assembly)

1No200mm diameter hcp roller

1no150mm diameter rubber roller

2no pneumatic cylinder for up and down pressure roll

10 hp motor with gear box as a drive

Pneumatic control panel

o All pneumatic components like Regulator, Flow Control, and Joint Pressure

Indicator valve 3 ways type and FRL unit for winder nip and brakes

o Centering guider E+L make

o Rewind and nip drive AC variable [standard make ]

5) Dust collector :

Dust collection unit complete with cotton bag inside with a lid on the box xo that dust is not thrown out and therefore collected in the bag and can be removed from the lid from time to time.

o 2 Nos. Top & Bottom Nylon brush arrangement with motor drive.

o 5 HP suction Blower for Liner cleaning

LINER REROLLING MACHINE

LINER WASHING + DRYING + REWINDING FOR TIRE INDUSTRY