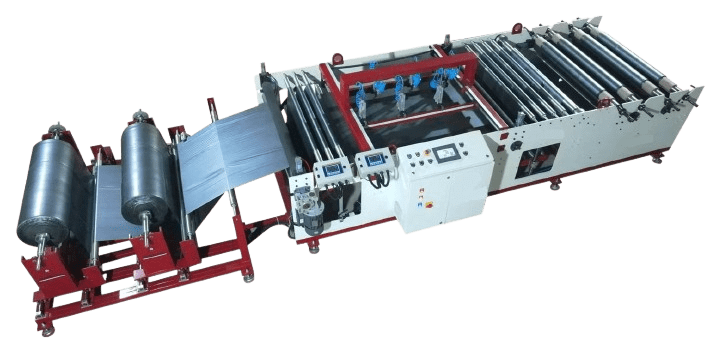

MULCH FILM PUNCHING MACHINE

FABRIC / FILM OPENER ALSO AVAILABLE IN FOLDING TYPE

WITH ONLINE PUNCHING ATTACHMENT.

KM TRIVEDI Mulch Film Punching Machine is a high-speed, four-wheel drive solution designed for precise and consistent hole punching in agricultural mulch films. These films are laid over soil to suppress weeds, retain moisture, and regulate soil temperature. The holes allow for planting crops while keeping the rest of the soil covered. With a working width of up to 1200 mm,/ 1400 mm / 1600 mm it incorporates advanced punching technology to deliver accurate hole patterns tailored to the needs of various crops.

The Role of Mulch Film in Agriculture

Mulch films are widely used in crop cultivation for a variety of important benefits.

These films help create an improved environment for plants to grow, which supports

better crop production overall.

- Moisture Retention: Mulch films reduce water evaporation from the soil

surface, which helps maintain consistent soil hydration.

- This is particularly helpful in arid areas where conserving water is

essential.

- By keeping moisture in the soil, plants receive a steady supply of water,

which encourages stronger root systems and healthier growth.

- This also lowers irrigation needs, saving water and reducing costs for

farmers.

- Weed Suppression: Mulch films block sunlight from reaching the soil, which

prevents the germination and growth of weeds.

- This natural weed control reduces the reliance on herbicides, making

farming more environmentally friendly and reducing chemical

expenses.

- The suppression of weeds also limits competition for water and

nutrients, allowing crops to thrive without interference.

- Soil Temperature Regulation: Different types of mulch films offer temperature

benefits customized to crop needs.

- In colder areas or during the early planting season, black mulch films

warm the soil by absorbing and holding onto heat.

- In contrast, white or silver mulch films reflect sunlight and help keep

the soil cooler during hot weather.

- This temperature management helps protect crops from extreme

conditions and promotes steady development.

- Enhanced Crop Growth: By combining moisture retention, weed suppression,

and temperature control, mulch films create a favourable microclimate for

plants.

- This environment promotes faster seed germination, improved

nutrient uptake, and stronger overall plant development.

|

|

|

|

1 | MULCH MACHINE WITH ONLINE PUNCHING ATTACHMENT. Heavy Duty structure . Plate Design ( Essar ) · Unwinder two stage complete assembly with Electronic ultrasonic web aligner system Fitting with 3” core holding air shaft assembly and mechanical break – 2 nos. · Nip roll assembly attach gear motor 1 HP AC & up/down dancing roll setting assembly – 1 nos. · Free roll 14 to 15 nos. with standard bearing assembly. · Punching platform with adjustable die setting size as per dimension with punches setting as per sample. Pneumatic assembly – 8 nos. · Punch size includes: – · 1 SET 24MM – 8 Punch with adjustable distance. · 64/65/75/55 – 6 set with adjustable line (any one size we will provide with machine)

OPTIONAL:- ( PUNCH ) 55MM WITH 6 PUNCH with cylinder:- 65MM WITH 6 PUNCH with cylinder:- 75MM WITH 6 PUNCH with cylinder:-

· Material cutting storage tank. · Servo motor 3 KW assembly with helical gear box attach nip roll assembly with a pneumatic system. · 4 vertical type winder assembly. · 4 Nos. winder air shaft assembly 3” core. · 5 HP AC motor with gear box & with clutch assembly. · Touch screen type HMI control panel complete. · Machine speed without punching = 160-10 m/min. Machine speed with punching = Up To 90- 120 m/min. ( Depends on material, Thickness width and draw length ) · Total power = 8 HP. · Auto stop meter · 76 mm ( 3 inch Air shafts on Unwind and Rewind ) · ( Any extra Air shaft out of this quotation will cost extra ) · Unwind Dia = 1000 mm. · Winding Dia = 500 mm for two & 400 mm for four. · Film width : 1500 mm · Type of film : Ld Mulch film

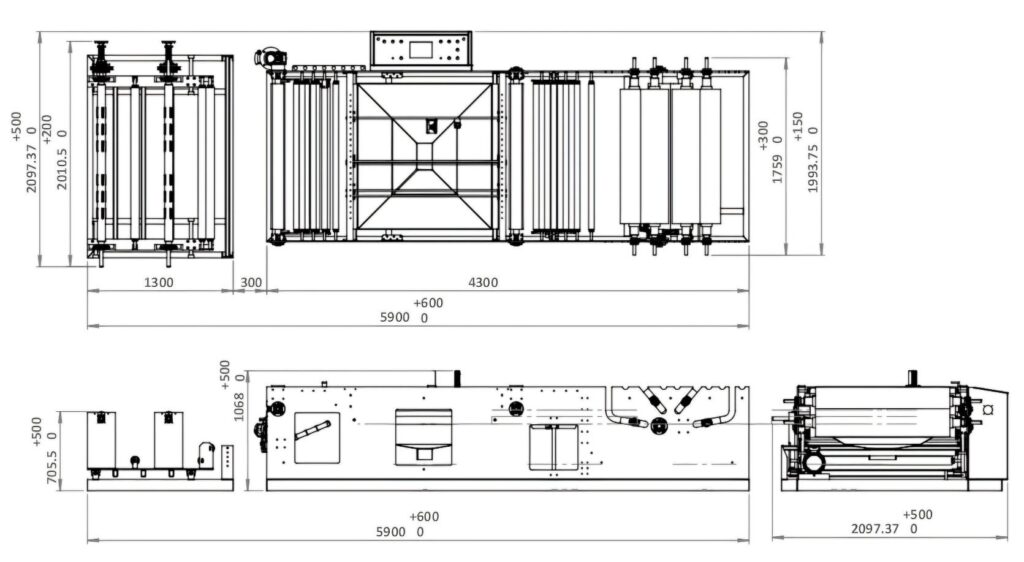

1. Machine dimensions: – Length = 20 feet (approx.) Width = 6.5 feet (approx.) Weight = 2.5 to 3 ton. 2. Motor and control panel: – 5 HP motor with gear box main drive 3 KW servo motor 1 HP motor with gearbox on nip SERVO MAKE ACTUATOR

Control panel: – HMI display panel Touch screen type HMI control panel complete. Total power: – 8 HP (approx.) Power : 3 phase earthling must be required Air compressor required : 3 HP , 7-8 bar pressure Tank capacity 200 Liter Note : Air compressor is not part of quotation and not included in machine price it is only for customer reference .

|

|

|