TURRET WINDERS

TURRET WINDERS

Specifications

Web widths: 500 mm – 2500 mm

Line speeds: 100-400 mpm

Roll weights: Up to 1000 kgs

Roll diameters: Up to 1200 mm

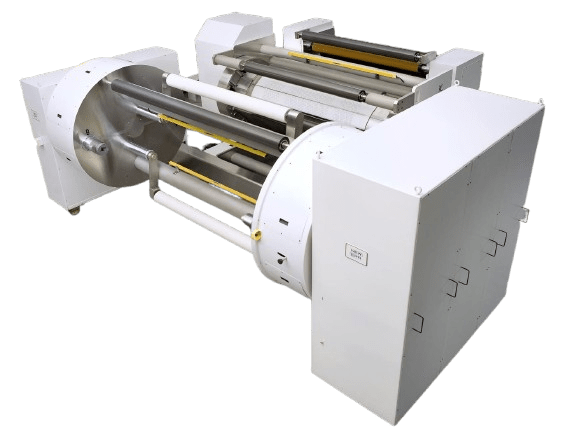

A turret rewinding machine is a type of machine used in the converting industry, particularly for slitting and rewinding materials like labels, films, and flexible packaging. It features a turret mechanism that allows for continuous, non-stop operation by automatically switching between winding stations. This significantly reduces downtime compared to traditional rewinding machines, improving overall production efficiency.

Technical Specification:

|

Working Width : 1150 to 4000mm |

Max. Dia. of The Inspected Roll : 400mm |

Speed : 0 to 100 mtrs./min |

Electric Power : 2-10 HP (Two Motor) |

Supply : 220W, 1 Phase, 50Hz |

TURRET WINDERS

Key features and benefits of a turret rewinding machine:

- Continuous operation:

The turret mechanism allows for seamless switching between winding stations, enabling continuous production without stopping to unload finished rolls.

- High speed and efficiency:

By eliminating downtime for roll changes, turret rewinders significantly increase production speed and efficiency.

- Automatic features:

Turret rewinders come with features like automatic core loading, splicing, and unloading, further minimizing manual intervention and maximizing automation.

- Versatility:

They can handle various materials, including paper, films, laminates, and label stock, making them suitable for a wide range of converting applications.

- Precision and control:

Turret rewinders often incorporate advanced tension control systems and precise slitting mechanisms for high-quality rewound rolls.

- Integration with other equipment:

They can be integrated with slitting machines, printing presses, and die-cutting machines to create a complete converting line.

A turret rewinder typically has multiple winding stations (often four) mounted on a rotating turret. As one roll is being wound, the turret rotates to bring a new, empty core into position. Once the first roll is full, the machine automatically splices the material to the new core, and the turret rotates again to bring the next core into position. This process continues seamlessly, allowing for continuous winding and minimizing downtime.

Applications:

Turret rewinding machines are used in various industries, including: Label printing and converting, Flexible packaging production, Film slitting and rewinding, and Paper and paperboard converting.